The rapid growth of electric vehicles is reshaping the UK’s transport landscape. As the UK progresses towards phasing out new petrol and diesel vehicles and accelerating zero emission adoption, lithium ion batteries are becoming central to this transition. These batteries are the foundation of electric mobility, yet far less attention is given to what happens once they reach end of life.

Understanding the full EV battery journey, from manufacture through use to automotive battery recycling and material recovery, is essential to building a resilient and sustainable supply chain for the future.

The Current EV Landscape in the UK

Electric vehicle adoption in the UK has grown significantly in recent years. According to the Climate Change Committee, EV sales continue to rise and now represent a substantial share of new vehicle registrations, supporting the UK’s carbon reduction pathway1.

Government policy remains a key driver. The Zero Emission Vehicle mandate requires 80 percent of new car sales to be zero emission by 2030, increasing to 100 percent by 20352.

Road transport remains one of the largest contributors to UK greenhouse gas emissions. Decarbonising transport through electrification is therefore fundamental to achieving Net Zero.

However, while EV adoption continues to expand, the long term impact on battery waste volumes must also be considered. As more EVs enter the market, more lithium ion batteries will eventually require compliant battery recycling and recovery solutions.

How an EV Lithium Ion Battery Is Manufactured

An EV lithium ion battery begins its life with the extraction of critical minerals such as lithium, nickel, cobalt and manganese. These materials are refined and processed into cathode and anode materials before being assembled into battery cells.

Cells are grouped into modules and integrated into battery packs, which include thermal management systems and battery management systems designed to ensure safety and performance.

Battery production is resource intensive and globally interconnected. Much of the mineral supply chain remains concentrated outside the UK. This global dependency highlights the importance of developing domestic solutions to recycle li ion battery materials and reduce reliance on virgin raw material extraction.

The Operational Life of an EV Battery

Once installed in a vehicle, the lithium ion battery undergoes repeated charge and discharge cycles over many years.

Key factors influencing lifespan include:

• Charging frequency and fast charging usage

• Operating temperature

• Driving style and load

• Depth of discharge

• Battery management efficiency

Industry research suggests that EV batteries typically last between 8 and 15 years, depending on usage conditions. Manufacturers commonly offer warranties of 8 years or approximately 100,000 miles.

Over time, batteries experience gradual capacity decline and increased internal resistance. Eventually, performance may no longer meet automotive requirements, prompting evaluation of next steps.

The Critical Decision: Repair, Reuse or Recycle

When an EV battery reaches the end of its automotive service life, it does not automatically become waste.

Possible pathways include:

• Repair or module replacement

• Repurposing into second life stationary storage applications

• Full automotive battery recycling

Second life deployment can extend value but requires detailed testing and safety validation. If reuse is not technically or economically viable, the responsible solution is to recycle li ion battery materials through established battery recycling processes.

The Faraday Institution has highlighted the importance of developing safe and efficient recycling routes to support the UK battery ecosystem3.

What Happens at End of Life?

When an EV battery reaches end of life, it enters a controlled and regulated recovery process. Automotive battery recycling is not a single standard method. The approach depends on battery chemistry, condition and the recovery technology used.

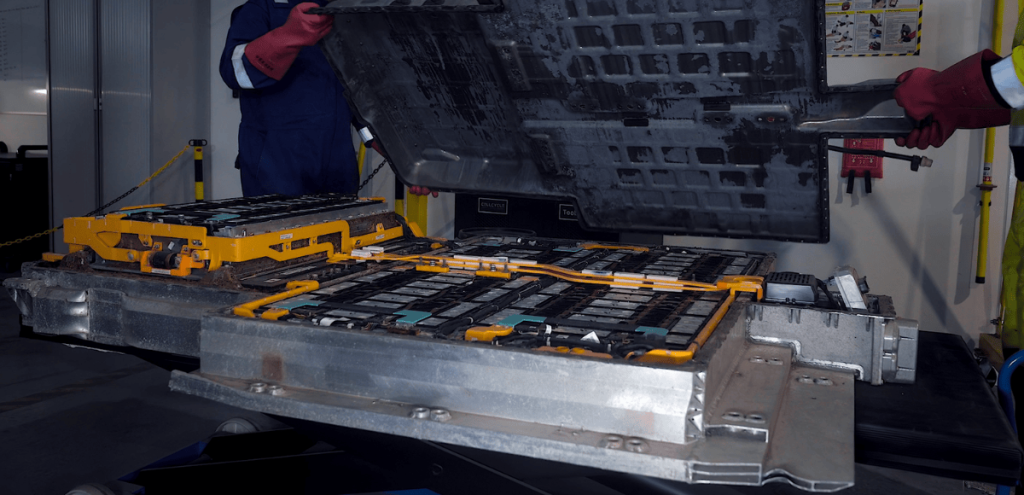

The first steps usually include:

• Safe collection and compliant transport

• Controlled discharge

• Dismantling of the battery pack

• Separation of internal components

In many recycling routes, mechanical processing produces black mass. This material contains lithium, nickel, cobalt and manganese, which are later refined and recovered4.

However, not all processes rely on black mass. Alternative methods, including bio-based and bioremediation technologies, can recover battery raw materials directly through controlled biological extraction. These approaches may reduce energy use and chemical intensity compared to traditional methods5.

Battery recycling is therefore more than waste treatment. It is a material recovery stage that enables critical minerals to re-enter the battery supply chain and support future EV production.

The UK Refining Challenge

Although the UK has developed battery collection and initial processing capacity, large scale refining capability remains limited. Much of the recovered black mass is exported for further processing overseas6.

This limits value retention within the UK and increases supply chain exposure. Developing domestic capability to recycle li ion battery materials and refine critical minerals locally would strengthen national resilience and align with broader industrial strategy objectives.

From End of Life to New Beginning: Closing the Loop

The EV battery life cycle must move beyond a linear model of disposal and towards a circular manufacturing system.

At Cellcycle, we operate as a dedicated lithium ion battery recycler, managing end of life batteries through safe, compliant and technically controlled processes. Our objective is not simply to process waste, but to enable the recovery of valuable materials that can re-enter the battery manufacturing supply chain.

Through automotive battery recycling, we will recover critical minerals from spent lithium ion batteries using our innovative LithiumCycle™ process. This bio-based recovery technology is designed to extract lithium, nickel, cobalt and manganese in a more sustainable and environmentally responsible manner.

By developing this capability within the UK, we aim to strengthen domestic battery material resilience, reduce reliance on virgin raw material extraction and support a more circular EV ecosystem.

End of life batteries should not represent the end of their value. Through advanced battery recycling and material recovery innovation, they can become the foundation of the next generation of battery production.