For businesses relying heavily on lithium-ion batteries—such as those in automotive, renewable energy storage, and industrial sectors—effective lithium battery disposal, decommissioning battery systems, and battery lifecycle management is crucial. Proper battery decommissioning is more than just compliance; it is essential for maintaining safety, environmental stewardship, and corporate responsibility. According to the International Energy Agency (IEA), the demand for lithium-ion batteries is projected to grow tenfold by 2030, amplifying the importance of responsible end-of-life lithium-ion battery disposal and management (IEA Battery Report).

When Should Companies Consider Battery Decommissioning?

Battery decommissioning becomes imperative in several scenarios, including when batteries reach their planned end-of-life, become defective, or are damaged during operation. Additionally, situations such as decreased battery performance, routine regulatory compliance audits, or safety incidents necessitate immediate attention and professional lithium-ion battery decommissioning actions. When decommissioning battery systems, the UK Environment Agency recommends proactive strategies to manage these batteries effectively to avoid compliance violations and environmental harm (UK Government Guidance).

Principles of Effective Battery Decommissioning

Battery decommissioning systematically dismantles and safely disposes of lithium-ion batteries to eliminate risks related to hazardous substances they contain. Compliance with stringent regulatory standards, including environmental and hazardous materials handling guidelines, is vital. Key regulations such as those stipulated by the Environment Agency and ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) mandate strict protocols for handling and transporting batteries to prevent environmental and public safety hazards. Adequate procedures for decommissioning battery systems are essential to meet these standards.

Engineers performing these tasks should be fully qualified and possess certifications in dangerous goods handling (DGSA), electrical engineering, IMI Tech Safe standards, and adherence to ISO safety guidelines. Such credentials ensure experts have a comprehensive understanding of battery chemistry, potential electrical risks, and compliant disposal practices, significantly reducing the associated risks.

Risks Associated with Improper Decommissioning

Improper battery decommissioning, particularly improper handling when decommissioning battery systems, can lead to critical safety risks including thermal runaway incidents (fires), leakage of hazardous chemicals, and severe environmental contamination. These incidents pose substantial health risks, can result in legal repercussions, substantial financial penalties, and significant damage to corporate reputation. According to the National Fire Protection Association (NFPA), lithium-ion battery-related fires are becoming increasingly common, underscoring the necessity of expert intervention (NFPA Report).

How Does Battery Decommissioning Typically Work?

The battery decommissioning process typically includes several critical stages:

- Assessment and Planning: Specialists thoroughly evaluate battery conditions, assessing the State of Health (SoH) and State of Charge (SoC), creating a tailored decommissioning strategy to minimise risks.

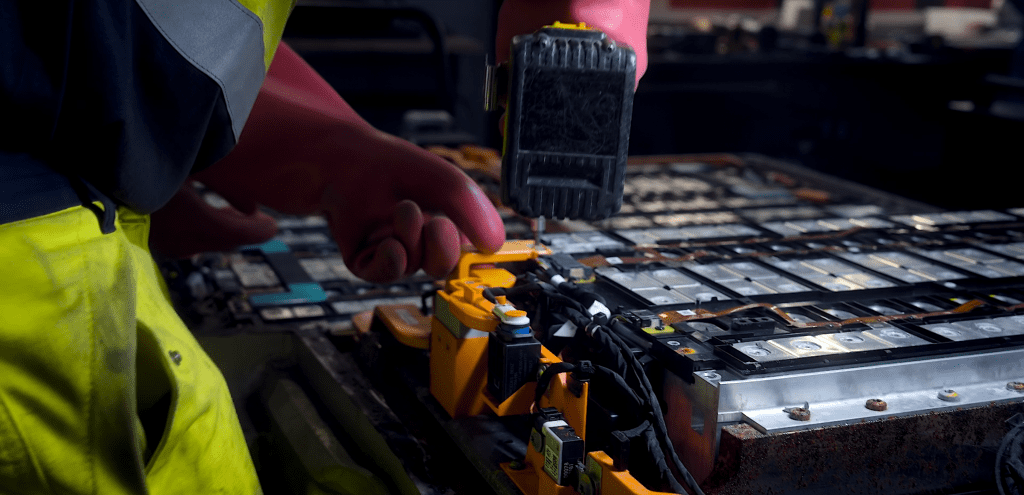

- On-site Battery Removal: Technicians equipped with specialised tools and safety gear perform on-site battery dismantling, significantly reducing hazards related to battery transportation.

- Packaging and Transport: Secure packaging compliant with ADR standards is utilised for safe transportation to certified recycling or disposal facilities.

- Documentation and Compliance: Comprehensive documentation, including Root Cause Analysis (RCA), ensures complete regulatory compliance and provides valuable insights for operational improvements. Experts in decommissioning battery systems ensure adherence to these processes thoroughly.

Expertise Required to Reduce Risks

Reducing risks during battery decommissioning demands extensive expertise, combining technical proficiency, regulatory awareness, and practical experience. Technicians should possess advanced training in hazardous material management, emergency response capabilities, and deep familiarity with operational protocols specific to different battery chemistries and conditions. Ongoing professional development is crucial for maintaining high standards and adhering to evolving industry guidelines.

Highlighting Cellcycle’s Rapid Response Unit

Cellcycle recognises the critical nature of immediate, professional intervention in lithium battery emergencies. Our dedicated Rapid Response Unit, comprising ADR-compliant vehicles and highly skilled technicians, delivers swift on-site support for urgent battery incidents. This rapid response capability ensures minimal operational downtime, significantly mitigates risks, and maintains the highest safety standards during emergencies.

Why Choose Cellcycle for Decommissioning Battery Systems?

At Cellcycle, we offer a fully integrated, nationwide solution for decommissioning battery systems and managing lithium ion battery disposal. Our certified engineers hold qualifications in hazardous goods handling, battery safety, and regulatory compliance. We operate a dedicated Rapid Response Unit, equipped with ADR vehicles and trained responders, to support businesses in urgent or complex battery decommissioning scenarios.

Our service covers:

- On-site battery system assessment and risk mitigation

- High voltage battery removal and isolation

- Compliant packaging and transportation

- End-of-life treatment and material recovery

- Comprehensive regulatory documentation

Whether you’re upgrading energy storage infrastructure, decommissioning legacy EV batteries, or responding to damaged battery assets, Cellcycle delivers fast, compliant, and sustainable solutions for decommissioning battery systems.