In a ground-breaking collaboration, Cellcycle has joined forces with Coventry University to revolutionise the recycling landscape for end-of-life lithium batteries. The partnership has received substantial funding from Innovate UK to develop its LithiumCycle™ process, which uses microorganisms to extract critical minerals, marking a significant step towards sustainable and environmentally friendly battery disposal solutions.

As the demand for lithium batteries continues to rise with the proliferation of electric vehicles, renewable energy storage, and portable electronic devices, there is a growing need for efficient and eco-friendly methods of handling end-of-life batteries. Recognising this challenge, Cellcycle and Coventry University are combining their expertise to create a pioneering recycling process that harnesses the power of biotechnology.

The innovative funding secured for this KTP project reflects a shared commitment to advancing sustainable practices in the field of battery recycling. By integrating bio-based techniques into recycling processes, Cellcycle and Coventry University aim to significantly reduce the environmental impact associated with traditional battery disposal methods that are high-energy intensive and produce waste acids.

Key features of the LithiumCycle™ process include:

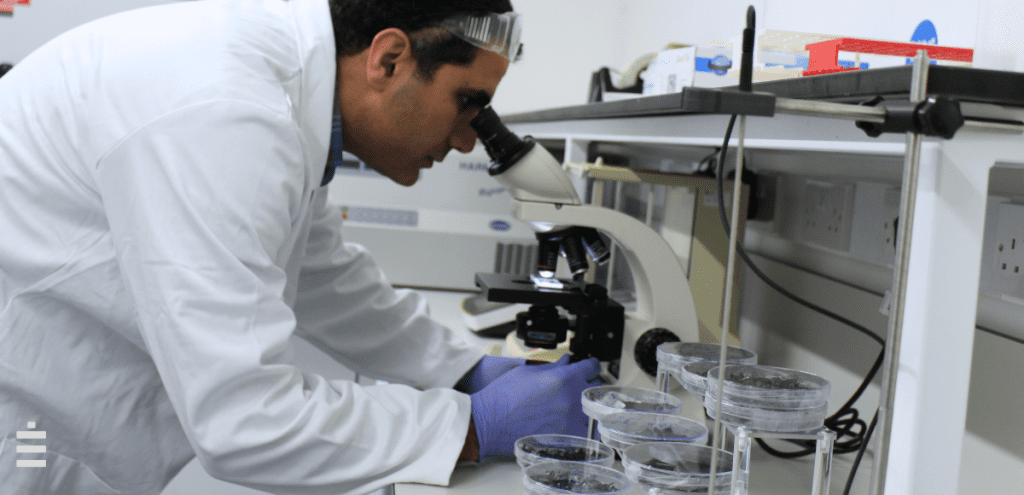

Microbial Degradation: Utilising specially engineered microorganisms to break down battery components in an environmentally friendly manner.

Resource Recovery: Maximising the recovery of valuable critical materials, such as lithium, cobalt, and nickel, from spent batteries through a bio-based extraction process.

Reduced Environmental Footprint: Minimising the release of harmful chemicals and emissions associated with traditional battery recycling methods using hydrometallurgy and pyrometallurgy.

Coventry University’s Bioleaching Research Group

The Bioleaching Research Group was created at Coventry University In 2017 by Professor Sebastien Farnaud to develop sustainable processes to recover precious metal from waste streams as a secondary source. The success of the group has led to a wider initiative to developed biotechnological applications for sustainability, which now in addition of recovering precious metals, also include projects of recycling plastic and other materials.

The work on bioleaching has been particularly successful in the recovery of metals from electronic waste, with numerous awards including the THE (Times Higher Education) Award 2023 for Best knowledge Transfer project 2023, the Innovate UK-KTP national award 2022 in the category “Changing the World”, and the NRA (National Recycling Award) 2021.

Prof. Farnaud, who created the Bioleaching Research Group at Coventry University, expressed excitement about the project’s potential impact, stating, “This collaboration represents a significant leap forward in sustainable battery recycling. By integrating bio-based processes, we aim to not only address the environmental challenges posed by end-of-life lithium batteries but also contribute to the circular economy by recovering valuable materials for reuse.

This is another application of Bioleaching technology to another waste stream, which expands its range of applications and confirm the suitability of biological systems for a sustainable circular economy.”

Gary Mo, Managing Director of Cellcycle and the SER Group, added, “We are proud to partner with Coventry University on this innovative initiative. Cellcycle is committed to advancing environmentally responsible practices in the battery recycling industry, and this collaboration aligns perfectly with our mission to drive positive change.”

The collaboration between Cellcycle and Coventry University exemplifies the power of knowledge transfer and public-private partnerships in driving innovation and addressing pressing environmental challenges. The LithiumCycle™ is expected to make substantial contributions to the development of a circular economy for lithium batteries, supporting the transition to a more sustainable and resource-efficient future.