Technology

Advanced battery

recycling technology

Utilising innovative, green technologies to sustainably treat li-ion batteries and recover critical minerals for the reuse in future battery production.

Advanced battery recycling technology

Working with our downstream partners we utilise a combination of mechanical, hydrometallurgical and solvent extraction processes to maximise both the value and the sustainable impact of all batteries recycled.

Cellcycle is currently developing one of the UK’s first in-house battery recycling processes where batteries are treated to recover battery materials without the need for exportation.

Hydrometallurgical Processing & Solvent Extraction

During the hydrometallurgical and solvent extraction process, the black mass is treated with a chemical precipitation methodology that allows the recovery of raw elements and minerals including hydroxides and carbonates.

The raw material that is recovered can then be put back into the battery manufacturing industry and reused in future battery products.

This process not only provides a more sustainable and environmental friendly solution for disposing of batteries but can help add value and reduce costs.

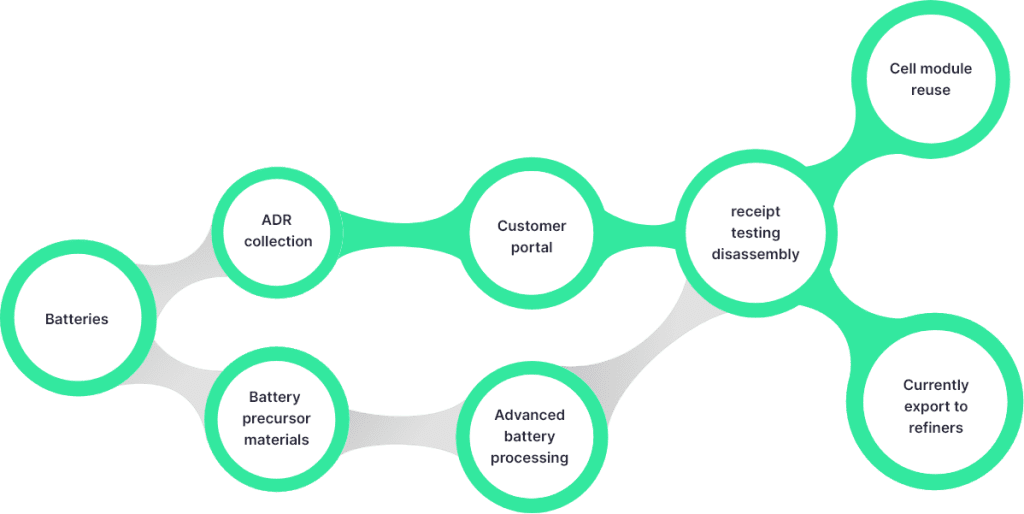

The Battery Recycling Process

Advanced Battery Recycling Facility

Cellcycle is working with R&D specialists and battery recycling experts to develop a dedicated and state-of-the-art battery recycling facility in the UK.

The new facility will enable Cellcycle to treat batteries directly in the UK, providing an environment perfect for the treatment and processing of batteries and recovered material.

Cellcycle’s new treatment facility will be equipped to meet all types of battery requirements organisations in the UK and across the globe may have and will be fully equipped for changes in legislation and rising demand for battery recycling and material recovery.